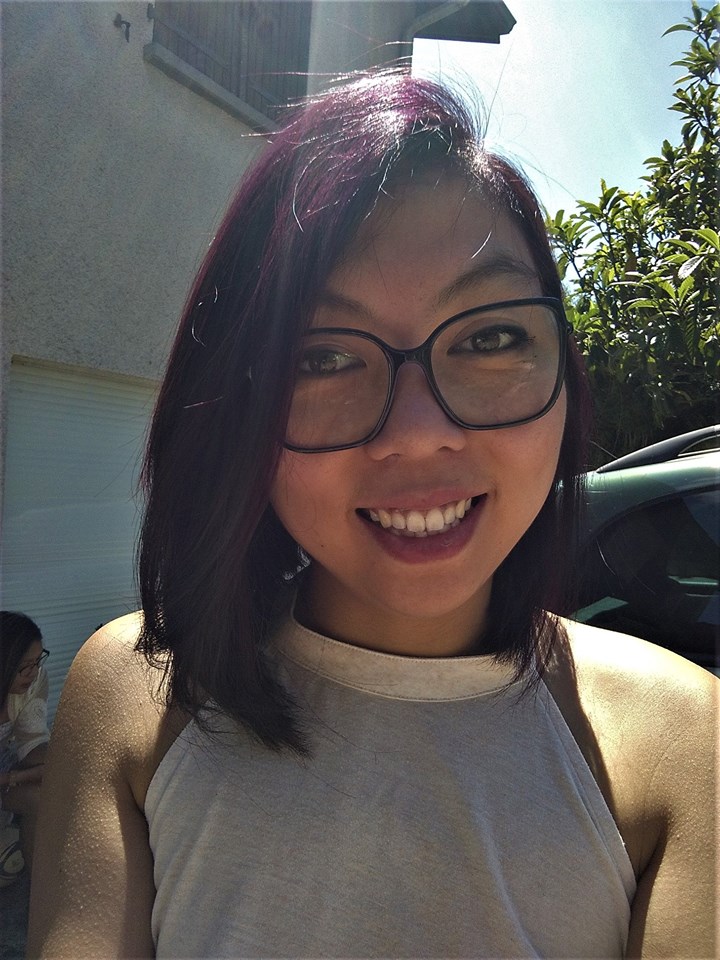

ESR4 - Kéo-Oudone Seymany

|

|

"Hi there! My name is Kéo-Oudone, but everyone calls me Kéo. I am the 4th member of the group and I am so grateful to be part of the SAMCAPS project! |

Kéo is a 28-years-old French graduate in Chemical Engineering. She received her Master's degree from CPE Lyon, where she specialized in dispersed media and applied formulation. Her role in SAMCAPS is to lead the project focusing on testing the performance and life-time of capsules when deposited on various surfaces (e.g. textiles, skin and hair). Capsule-surface interactions are expected to vary as a function of the different copolymer characteristics such as functional groups, molecular weight, hydrophobicity/hydrophilicity balance, type of self-assembly, degree of cross-linking. These are the main role players in determining the stiffness, strength, release kinetics, and other key parameters that need to be carefully measured to improve the deposition of the capsules on surfaces.

Kéo is enrolled at Florence University. The first half of her PhD is being spent in Brussels at P&G, where she is training in the targeted delivery of particles, focusing first on fabrics but later on as well on hair, skin, floors etc. She is learning state-of-the-art techniques to measure deposition on fabric and hair, and will be trained in the current know-how concerning the enhancement of active deposition on said surfaces. She will study how the polymer capsules will deposit on hair and fabric and will develop a programme leveraging on surface energy understanding, particle size control, and polymer coating of capsules in order to enhance the deposition of capsules and actives.

Among the analytical techniques to be used for this scope are confocal Raman spectroscopy, zeta potential measurement, surface energy measurement via nanoindentation. The goal is to develop correlations between the various capsule surface properties and the deposition of the capsules. The deposition of the capsules on the surface itself will be measured after training in fluorescent, GCMS and TOF-SIMS methodologies.

After 18 months, Kéo will move to Florence to work in CSGI. Here, she will rely on the work carried out by ESR1 and ESR2 to select the best performing capsule systems and set up a method to characterize the deposition, aging and release of actives on surfaces. Since such parameters are significantly affected by the adhesive and mechanical properties of the systems, she will receive extensive training in atomic force microscopy to characterize the surfaces, in force measurements to assess the adhesive properties of the capsules, and in rheology to analyze their dynamical (storage and loss) elastic properties. She will benefit from the wide range of instruments available at CSGI to characterize the surface tension and contact angle of the capsule dispersions. In collaboration with the CSGI unit of Rome, Kéo will develop reproducible techniques for the assessment and control of wall integrity and thickness in nanostructured microcapsules, based on Focused Ion Beam (FIB) microscopy techniques.